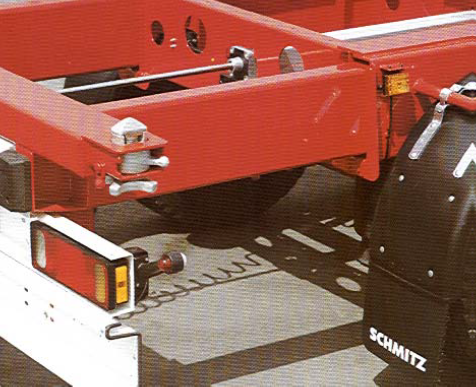

6.1 Swap bodies are carried by road on dedicated carrier vehicles. The corner fittings of the swap body fit onto cones of locking devices (twistlocks) which, by turning the cones, provide a form closure between the swap body and the vehicle structure (see figure 2.1).

Figure 2.1 Twistlock on a road vehicle

6.2 Freight containers should be carried by road on purpose built container chassis, where the freight container is supported by the four corner fittings. The corner fittings of the freight container fit onto the twistlocks cones of the chassis, similar to the securing devices described in 6.1.

6.3 When carried by rail, swap bodies and freight containers are loaded on open wagons which are specifically fitted with stacking or locking devices. Semi-trailers may be carried on wagons equipped with dedicated bedding devices for accommodating road vehicles.

6.4 Container vessels are specifically constructed for the carriage of freight containers. Cargo spaces under deck or cargo spaces on hatchless container vessels are equipped with cell guides, where the freight containers are stacked, obtaining sufficient hold and securing. 20‑foot freight containers may be stowed in 40‑foot cell guides, provided that suitable stacking cones are inserted into the corner fittings of the freight containers. Freight containers carried on deck are affixed to the ships structure by means of twistlocks. Twistlocks are used also to interconnect freight containers stowed one on top of another. In addition, container stacks on deck are secured to the ships structure by means of lashing rods and tensioning devices (bottle screws) (see figure 2.2). Details of the securing arrangement are described in the Cargo Securing Manual of the individual ship.

Figure: 2.2 Cell guides and lashing rods on a container vessel

6.5 When carried on general cargo ships which are not specifically constructed for the carriage of freight containers, the freight containers are secured to the ships structure by means of lashing chains or wire ropes and tensioning devices (see IMO Code of Safe Practice for Cargo Stowage and Securing, Annex 1). Further details are described in the Cargo Securing Manual of the individual ship.

6.6 When vehicles are loaded in a vehicle deck of a ro-ro ship, the parking brakes should be applied and locked, engines should be in gear. Uncoupled semi-trailers should not be supported on their landing legs but preferably supported by a trestle or similar device. Lashings which are attached to the securing points of the vehicle should be connected with hooks or other devices so designed that they cannot disengage from the aperture of the securing point if the lashing slackens during the voyage. Only one lashing should be attached to any one aperture of the securing point on the vehicle. Further details are described in the Cargo Securing Manual of the individual ship.

6.7 The wheels of railcars shunted into the rail deck of a railway ferry should be chocked on the rail with appropriate steel chocks. The wagons should be secured to the ships structure with chains and tensioning devices (bottle screws). In case of severe weather conditions, the spring system of the wagons should be released by use of specific trestles. Further details are described in the Cargo Securing Manual of the individual ship.