Page History

...

2.1.2 Timber planks or scantlings may may also be used for creating gaps between parcels of cargo in order to facilitate natural ventilation, particularly in ventilated containers. Moreover, the use of such dunnaging is indispensable, when packing reefer containers.

2.1.3 Timber planks, plywood sheets or pallets may be used to equalize loads within stacks of cargo parcels and to stabilize these stacks against dislocation or collapse. The same material may be used for separating packages, which may damage each other or even for installing a temporary floor in a CTU for eliminating inappropriate stack loads to the cargo (see figure 7.2).

...

2.1.5 Dunnaging material, in particular sheets of plastic or paper and fibre nets may be used for separating unpackaged cargo items, which are designated for different consignees consignees.

2.1.6 The restrictions on the use of dunnaging materials with regard to quarantine regulations, in particular wood or timber, should be kept in mind (see sections 1.13 and 1.14 of this annex).

...

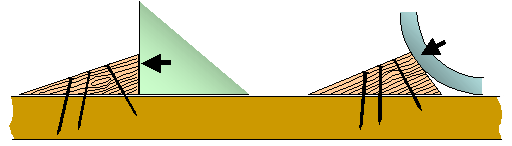

2.3.5 Blocking by nailed on scantlings should be used for minor securing demands only. Depending on the size of the nails used, the shear strength of such a blocking arrangement may be estimated to take up a blocking force between 1 and 4 kN per nail. Nailed on wedges may be favourable for blocking round shapes like pipes. Care should be taken that wedges are cut in a way that the direction of grain supports the shear strength of the wedge. Any such timber battens or wedges should only be nailed to dunnage or timbers placed under the cargo. Wooden floors of closed CTUs are generally not suitable for nailing. Nailing to the softwood flooring of flatracks or platforms and open CTUs may be acceptable with the consent of the CTU operator (see figure 7.7).

Figure 7.7 Properly cut and nailed wedges |

2.3.6 In the case of form locking, void spaces should be filled and may be favourably stuffed by empty pallets inserted vertically and tightened by additional timber battens as necessary. Material which may deform or shrink permanently, like rags of gunny cloth or solid foam of limited strength, should not be used for this purpose. Small gaps between unit loads and and similar cargo items, which cannot be avoided and which are necessary for the smooth packing and unpacking of the goods, are acceptable and need not to be filled. The sum of void spaces in any horizontal direction should not exceed 15 cm. However, between dense and rigid cargo items, such as steel, concrete or stone, void spaces should be further minimized, as far as possible.

...

2.4.2 The relation between MSL and the breaking strength is shown in the table below. The figures are consistent with Annex 13 of the IMO Code of Safe Practice for Cargo Stowage and Securing. Corresponding relations according to standards may differ slightly.

...

2.4.18 Modular lashing systems with ready-made web lashings are available in particular for general purpose freight containers, to secure cargo against movement towards the door. The number of lashings should be calculated depending on the mass of the cargo, the MSL of the lashings, the lashing angle, the friction factor, the mode of transport, and the MSL of the lashing points in the freight container.

...