1.1 When applicable, planning of packing should be conducted as early as possible and before packing actually commences. Foremost, the fitness of the envisaged CTU should be verified (see chapter 7 of this Code). Deficiencies should be rectified before packing starts.

1.2 Planning should aim at producing either a tight stow, where all cargo packages are placed tightly within the boundaries of the side and front walls of the CTU, or a secured stow, where packages do not fill the entire space and will therefore be secured within the boundaries of the CTU by blocking and/or lashing.

1.3 The compatibility of all items of cargo and the nature, i.e. type and strength, of any packages or packaging involved should be taken into account. The possibility of cross-contamination by odour or dust, as well as physical or chemical compatibility, should be considered. Incompatible cargoes should be segregated.

1.4 In order to avoid cargo damage from moisture in closed CTUs during long voyages, care should be taken that other wet cargoes, moisture inherent cargoes or cargoes liable to leak are not packed together with cargoes susceptible to damage by moisture. Wet timber planks and bracings, pallets or packagings should not be used. In certain cases, damage to equipment and cargo by condensed water dripping from above may be prevented by the use of protective material such as polythene sheeting. However, such sheeting or wrapping may promote mildew and other water damage, if the overall moisture content within the CTU is too high. If drying agents are to be used, the necessary absorption capacity should be calculated. More information may be found in annex 3.

1.5 Any special instructions on packages, or otherwise available, should be followed, e.g.:

- Cargoes marked "this way up" should be packed accordingly;

- Maximum stacking height marked should not be exceeded.

Note: See appendix 1 to this annex for further details on packaging marks.

1.6 Where packing results in stacks of packages, the strength of the individual packages should be capable of supporting those placed above them. Care should be taken that the stacking strength of packages is appropriate for the stack design.

1.7 Consideration should be given to potential problems, which may be created for those persons who unpack the CTU at its destination. The possibility of cargo falling out when the CTU is opened should definitely be avoided.

1.8 The mass of the planned cargo should not exceed the maximum payload of the CTU. In the case of freight containers, this ensures that the permitted maximum gross mass of the freight container, marked on the CSC safety approval plate, will not be exceeded. For CTUs not marked with their maximum permissible gross mass or payload, these values should be identified before packing starts.

1.9 Notwithstanding the foregoing, any limitation of height or mass along the projected route that may be dictated by regulations or other circumstances, such as lifting, handling equipment, clearances and surface conditions, should be complied with. Such mass limits may be considerably lower than the permitted gross mass referred to above.

1.10 When a heavy package with a small "footprint" will be shipped in a CTU, the concentrated load should be transferred to the structural transverse and longitudinal bottom girders of the CTU (see section 3.1 of this annex for details).

1.11 In longitudinal direction the centre of gravity of the packed cargo should be within allowed limits. In transverse direction the centre of gravity should be close to the half width of the CTU. In vertical direction the centre of gravity should be below half the height of the cargo space of the unit. If these conditions cannot be met, suitable measures should be taken to ensure the safe handling and transporting of the CTU, e.g. by external marking of the centre of gravity and/or by instructing forwarders/carriers. In case of CTUs, which will be lifted by cranes or container bridges, the longitudinal centre of gravity should be close to a position at half the length of the CTU (see appendix 4 to this annex).

1.12 If the planned cargo of an open-topped or open-sided CTU will project beyond the overall dimensions of the unit, suitable arrangements should be made with the carriers or forwarders for accommodating compliance with road or rail traffic regulations or advising on special stowage locations on a ship.

1.13 When deciding on packaging and cargo-securing material, it should be borne in mind that some countries enforce a garbage and litter avoidance policy. This may limit the use of certain materials and imply fees for the recovery of packaging at the reception point. In such cases, reusable packaging and securing material should be used. Increasingly, countries require timber dunnage, bracings and packaging materials to be free of bark.

1.14 If a CTU is destined for a country with wood treatment quarantine regulations, care should be taken that all wood in the unit, packaging and cargo complies with the International Standards for Phytosanitary Measures, No. 15 (ISPM 15)[1].This standard covers packaging material made of natural wood such as pallets, dunnage, crating, packing blocks, drums, cases, load boards and skids. Approved measures of wood treatment are specified in Annex I of ISPM 15. Wood packaging material subjected to these approved measures should display the following specified mark:

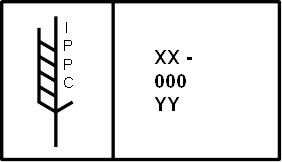

Figure 7.1 Phytosanitary mark |

The marks indicating that wood packaging and dunnage material has been subjected to approved phytosanitary treatment in accordance with the symbols shown in figure 7.1 will have the following components:

1.14.1 Country code

The country code should be the International Organization for Standardization (ISO) two letter code (shown in the figure as “XX”).

1.14.2 Producer/treatment provider code

The producer/treatment provider code is a unique code assigned by the national plant protection organization to the producer of the wood packaging material, who is responsible for ensuring that appropriate wood is used (shown in the figure as “000”).

1.14.3 Treatment code

The treatment code (shown as “YY” in the figure) shows the abbreviation for the approved measure used (HT for heat treatment, MB for fumigation with methyl bromide). In Europe the letters “DB” can be added where debarking has been done.

Note: Treatment should be carried out before the packaging and dunnage material is packed into the CTU. In situ treatment is not permitted.

1.15 Damaged packages should not be packed into a CTU, unless precautions have been taken against harm from spillage or leakage (see also chapter 10 of this Code on dangerous goods). The overall capability to resist handling and transport stresses should be ensured.

1.16 The result of planning the packing of a CTU may be presented to the packers by means of an oral or written instruction or by a sketch or even scale drawing, depending on the complexity of the case. Appropriate supervision and/or inspection should ensure that the planned concept is properly implemented.

[1] Secretariat of the International Plant Protection Convention, Food and Agriculture Organization of the United Nations: Regulation of wood packaging material in international trade.