1.1 Freight containers used in international transport and, under certain conditions, also swap bodies and road trailers are required by applicable regulations to bear safety approval plates.

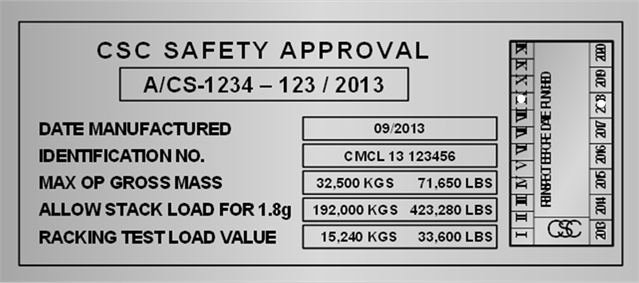

1.2 Under the International Convention for Safe Containers (CSC), each freight container is required to bear a safety approval plate permanently affixed to the rear of the freight container, usually the left hand door. On this plate, the most important information for the packer is:

- The date manufactured;

- The maximum gross mass1; and

- The allowable stacking mass,

as shown in figure 4.1.

Figure 4.1 Diagram of CSC safety approval plate

1.2.1 The CSC requires freight containers to be thoroughly examined 5 years after manufacture and subsequently at least every 30 months. The date of the next periodic examination is stamped on the approval plate or affixed to it in form of a decal (see figure 4.2).

Figure 4.2 CSC safety approval plate with next examination date

1.2.2 As an alternative to such periodic inspections, the owner or operator of the freight container may execute an approved continuous examination programme where the freight container is frequently inspected at major interchanges. Freight containers operated under such programme should be marked on or near to the safety approval plate with a mark starting “ACEP” followed by numerals and letters indicating the approval number of this continuous examination programme (see figure 4.3).

Figure 4.3 Safety approval plate with ACEP mark

1.3 Swap bodies and road trailers destined for transport by rail within the European railway network require a marking as per EN 13044 2 . This operational marking provides information for codification and for approval of the swap body or semi-trailer for rail transport.1.2.3 If there is no ACEP mark and if the next examination date is already elapsed, or is before the expected arrival time of the freight container at its destination, the freight container should not be used in intermodal or international transport.

Figure 4.4 Yellow operational mark for swap bodies |

Figure 4.5 Yellow operational mark for trailers |

1.3.1 The data on the plates shown in figures 4.4 and 4.5 relate to dimensions of CTU and how they can fit onto rail wagons. The significant information relates to the characters “XL” shown on both plates. This indicates the strength of the swap bodies’ body, standard or reinforced, with the marking referring to EN 12642 (see also figure 4.6).

Component | Standard structure | Reinforced structure |

Front wall | 0.4P and maximum limita | 0.5P without maximum limit |

Rear wall | 0.25P and maximum limitb | 0.3P without maximum limit |

Side wall | Up to 0.3P | 0.4Pc |

a 5,000 daN b 3,100 daN c Except for double-decker | ||

Figure 4.6 Static test conditions | ||

1.3.2 The XL test requirements specifically apply to the following types of body structures:

- box type;

- drop side with side and tail boards without cover;

- drop side with side and tail boards with tarpaulin cover;

- curtain-siders.