3.1 Stance

3.1.1 The height of the door handle and the seal varies depending on the type of CTU and the design of the door. Rigid vehicles and trailers are generally lower within a range of 1.1 and 1.6 m from the ground. Freight containers carried on a trailer will have the security cam fitted seal approximately 1.4 m from the ground, but the handles and any seals attached to them at a height of approximately 1.9 m (see figures 5.9 and 5.10).

Figure 5.9 Seal heights - trailer |

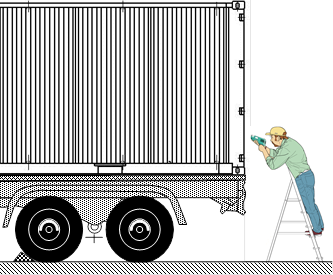

Figure 5.10 Seal heights - freight container |

3.1.2 Seals attached to handles on container doors (approximately 1.9 m above the ground) will be about head height for the average person and attempting to cut through a bolt seal at that height is likely to result in a musculoskeletal injury.

3.1.3 The best posture for cutting seals is for the operator to stand upright with the angle at the elbow between 90° and 120° and the elbow in line or slightly forward of the body.

3.1.3.1 Avoid positions where the elbows are behind the body or above the shoulder.

3.1.3.2 When gripping the cutting tool, the wrist should be kept as straight as possible.

3.1.3.3 The best position of the cutting head will be approximately 0 to 15 cm above the height of the elbow. The height above ground level to the elbow for the average (western) man is 109 cm. This means that the best position for the seal will be between 109 and 124 cm (1.09 and 1.24 m) above standing level.

3.1.4 Figure 5.11 shows a typical example of how many seals are actually cut. The operator has his back bent, the seal is well below the height of the elbow, the arms are almost straight and the left wrist is cocked, while the right appears to be straight.

Figure 5.11 Cutting the seal

3.1.5 The length of the bolt cutter levers are very long compared to the movement of the cutting blades, therefore the hands have to “squeeze” in a considerable distance.

3.1.6 Cutting resistance is high as the blades start to cut and reduces to grow again as the cut finishes. Therefore while the hands are wide apart the greatest inwards pressure is required.

3.2 Height adjustment

3.2.1 The normal height for the seals above ground level is between 1.09 and 1.24 m. This means that a normal person when cutting the lower seal position of a freight container mounted on a trailer and with an ideal stance would have their feet approximately 16 cm above ground level. For the higher seal position the foot position would be about 50 cm above the ground.

3.2.2 It is essential that the operator is able to gain a firm footing when cutting the seal. This may require the legs to be spread both laterally and longitudinally. The footing should be:

- Non-slip;

- Level;

- Free from debris and loose items.

There should also be no trip hazard or risk of the operator falling.

3.2.3 For cutting the seal at the lower position a single pallet with a plywood panel fixed to the top, or two pallets stacked with a plywood panel, all fixed together so that there is no risk of the items sliding independently would provide a suitable platform. However there is a risk of the operator accidentally falling from the platform during the cutting operation.

3.2.4 To access the highest seals, the use of a proprietary platform with a narrow work platform width may not allow the operator to stand comfortably and safely as the depth may not be sufficient. A second platform with a plywood panel fixed to both will allow sufficient area for the operator to stand and operate the bolt cutters safely (see figure 5.12). Such platforms should also be fitted with fall protection by way of barriers.

Figure 5.12 Work platform

3.2.5 Mobile work platforms similar to the one shown in figure 5.13 may be rather more sophisticated than is required and a smaller version may be more appropriate (see figure 5.14). As an alternative a simpler device can be fitted to the tines of a forklift truck as shown in figure 5.15.

Figure 5.13 Mobile work platform | Figure 5.14 Mobile work device | Figure 5.15 Mobile work station |

3.2.6 The important feature of a mobile work platform is that it can be adjusted to exactly the correct height, has a platform of sufficient area and provides the operator with full fall protection.

3.2.7 A ladder can be used, but this is not a really suitable platform for cutting with large bolt cutters. For smaller cutters they may be used with care.

3.2.7.1 When carrying out a task using a ladder or a step ladder it is essential that three points of contact (hands and feet) are maintained at the working position. Since both hands are required to cut the seal using the bolt cutters, the third point of contact can be substituted by leaning the chest on the ladder or step ladder.

3.2.7.2 Working on a ladder or step ladder should not involve any side loading which necessitates twisting of the body, therefore it is improbable that a ladder can be positioned so as to comply with these requirements and provide sufficient room for the bolt cutters to be operated correctly.

3.2.7.3 Therefore if there is a choice only between a ladder and a step ladder the step ladder will probably provide the better work position.

3.2.8 Figure 5.16 shows the correct position for the operator with the bolt cutters held between the step ladder and the CTU.

3.2.9 In this position there is still a risk of the ladder falling sideways as the cutters are squeezed in, therefore the operator should be supported by a co-worker or the step ladder secured to prevent it falling or sliding.

3.2.10 A safer solution is to use wide mobile steps with a top platform sufficiently wide and deep to permit the operator to stand safely.

Figure 5.16 Working on container doors