8.2.1 Approval plates

8.2.1.1 Freight containers and, under certain conditions, also swap bodies and road trailers may be required by applicable regulations to bear a safety approval plate. Details of the markings required on swap bodies and road trailers destined for transport by rail within the European railway network and data plates on freight containers transported internationally by sea and covered by the International Convention for Safe Containers (CSC) are shown in annex 4.

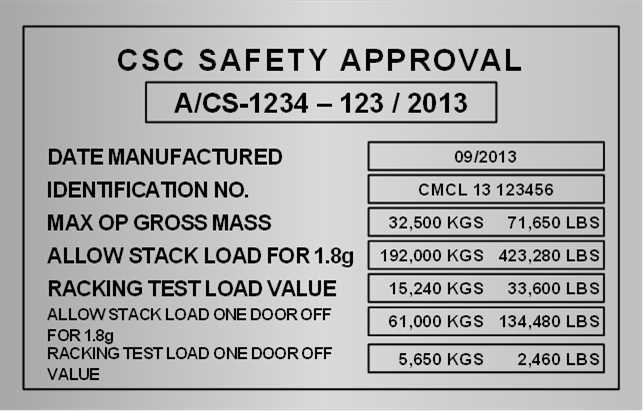

8.2.1.2 The safety approval plate as required by the CSC should be permanently affixed to the rear of the freight container, usually the left hand door. On this plate, the most important information for the packer are:

- The maximum gross mass. This is the maximum mass of the packed freight container and should never be exceeded.

- The allowable stacking mass (see annex 4, section 3 for more information). Freight containers having an allowable stacking mass of less than 192,000 kg are not suitable for unrestricted transport by sea (see paragraph 7.3.1).

If there is no CSC approval plate, the freight container should not be used in international traffic.

8.2.1.3 The CSC requires freight containers to be thoroughly examined 5 years after manufacture and subsequently at least every 30 months and two methods are used by the container industry for recording that the freight container is fit for use. Both methods require marks to be shown on or near to the safety approval plate:

8.2.1.3.1 The date of the next periodic examination is stamped on the approval plate or affixed to it in form of a decal. The date of the next examination shown in figure 8.1 is September 2018.

Figure 8.1 CSC safety approval plate with next examination date

Figure 8.2 CSC safety approval plate with ACEP mark

8.2.1.4 If there is no ACEP mark and if the next examination date is already elapsed, or is before the expected arrival time of the freight container at its destination, the freight container should not be used in intermodal or international traffic.8.2.1.3.2 As an alternative to such periodic inspections, the owner or operator of the freight container may execute an approved continuous examination programme where the freight container is frequently inspected at major interchanges. Freight containers operated under such a programme should be marked on or near to the safety approval plate with a mark starting “ACEP” followed by numerals and letters indicating the approval number of this continuous examination programme (see figure 8.2).

8.2.1.5 The practice of transporting cargo in one door open or one door removed freight containers is inherently dangerous and therefore is strongly discouraged. The practice is illegal unless it is marked on the CSC plate (see figure 8.3). Additionally, there may be negative consequences to using this practice in the supply chain (e.g. terminals refusing to handle open door freight containers).

Figure 8.3 CSC safety approval plate for one door off operation

8.2.2 Exterior checks

8.2.2.1 The structural framework, the walls and roof of a CTU should be in good condition, and not significantly distorted, cracked or bent. The CTU operator is responsible for delivering a CTU that complies with international structural integrity requirements and international or national safety regulations. If the structural integrity is in doubt, advice should be sought from supervisory personnel or the CTU operator.

8.2.2.2 The doors of a CTU should work properly and be capable of being securely locked and sealed in the closed position, and properly secured in the open position. Door gaskets and weather strips should be in good condition.

8.2.2.3 A folding CTU with movable or removable main components should be correctly assembled. Care should be taken to ensure that removable parts not in use are packed and secured inside the unit.

8.2.2.4 Any component that can be adjusted or moved, or a pin that can be engaged and withdrawn, should be checked to see that it can be moved easily and retained correctly. This is of particular importance for folding flatracks where the end-walls are retained in the upright position by a pin or shoot bolt which should be engaged and retained from accidentally pulling out by a retaining flap.

8.2.2.5 Removable or swinging headers of open top CTUs should be inspected. The header is generally supported by removable pins. Checks should be made to ensure that the pins are of the correct length and freely removable at both ends. Checks should also be made for signs of cracks around the hinges.

8.2.2.6 Road vehicles that are likely to be carried on rail wagons or on ro-ro ships should be provided with points for securing them. There should be equal numbers of lashing points on both sides of the vehicle and each point should be intact and free from serious corrosion or damage.

8.2.2.7 For sheeted vehicles or containers the side, top or all round covers should be checked as being in satisfactory condition and capable of being secured. Loops or eyes in such canvas which take the fastening ropes, as well as the ropes themselves, should be in good condition. All lashing strap ratchet tighteners should be able to be engaged and operate correctly.

8.2.2.8 Labels, placards, marks or signs regarding previous usages of the CTU should be removed. Permanently affixed signs and marks may never be removed.

8.2.2.9 When undertaking the exterior checks, the CTU should be checked for any signs of recontamination particularly:

- Along bottom rails;

- Within forklift pockets;

- In and around the twist lock fittings;

- Underside and cross members;

- On tops where necessary.

8.2.3 Interior checks

8.2.3.1 Before entering a closed CTU, the doors should be opened for a period of time - enough to allow the internal atmosphere to regularize with the ambient. Care should be taken to ensure that during this period, animals and insects should not enter the CTU.

8.2.3.2 The CTU should be free from major damage, with no broken flooring or protrusions such as nails, bolts, special fittings, etc. which could cause injury to persons or damage to the cargo.

8.2.3.3 The CTU should not show liquids or persisting stains on flooring and side walls. There are a number of different materials and surface treatments used for flooring in CTUs. Sealed surfaces generally can be cleaned with absorbent materials. Where a stain can be transferred by wiping a gloved hand over it, the CTU should not be used and a replacement CTU should be requested.

8.2.3.4 A CTU should be weatherproof unless clearly designed otherwise (e.g. flatrack). Patches or repairs to solid walls should be carefully checked for possible leakage by looking for rusty streaks below patches. Repairs to side and roof sheets should have a fully stitched patch covering all of the hole with a substantial overlap.

8.2.3.5 Potential points of leakage may be detected by observing whether any light enters a closed unit. Standard and approved procedures for identifying pin holes and other points of leakage should be adopted.

8.2.3.6 Cargo tie-down cleats or rings, where provided, should be in good condition and well anchored. If heavy items of cargo are to be secured in a CTU, the operator should be contacted for information about the cleat strength and appropriate action taken.

8.2.4 Cleanliness

8.2.4.1 All CTUs should be provided clean and free from contamination, but the type will dictate the standard that can be expected.

8.2.4.2 Closed CTUs should be clean, dry and free of residue and/or persistent odours from previous cargo.

8.2.4.3 Open CTUs should be free from debris and as dry as is possible.

8.2.4.4 Following receipt of the CTU the packer should prevent recontamination. Examples of recontamination will be the presence of any of the following:

- Soil;

- Plants/plant products/debris;

- Seeds;

- Moths, wasps and bees;

- Snails, slugs, ants and spiders;

- Mould and fungi;

- Frass (insect and bird droppings or waste);

- Egg sacs;

- Animals (including frogs), animal parts/blood/excreta and reproductive components or parts thereof;

- Other contamination that shows visible signs of harbouring pests or invasive alien species (including alien species which carry risks of becoming invasive at the site of arrival of CTUs).